×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Acura Parts

- Acura Accessories

My Garage

My Account

Cart

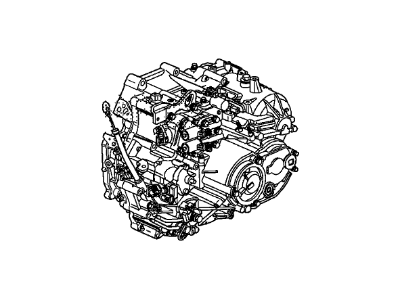

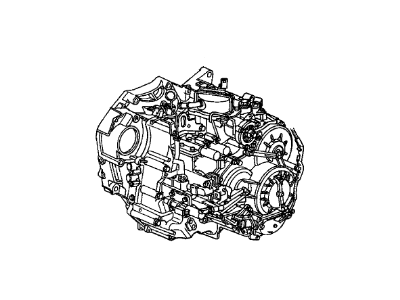

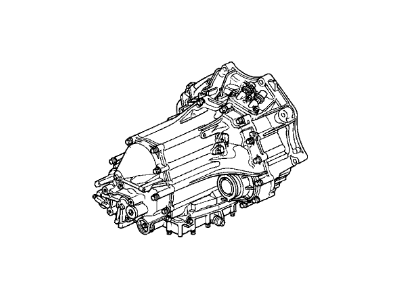

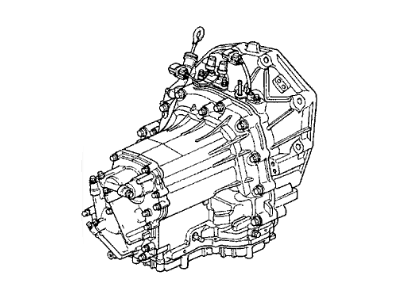

Genuine Acura TL Transmission Assembly

Trans Assembly- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

23 Transmission Assemblies found

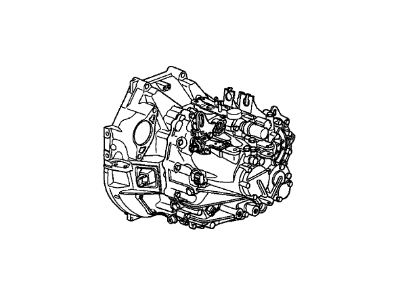

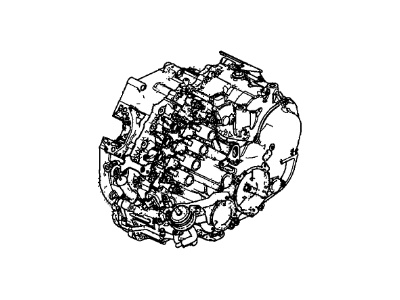

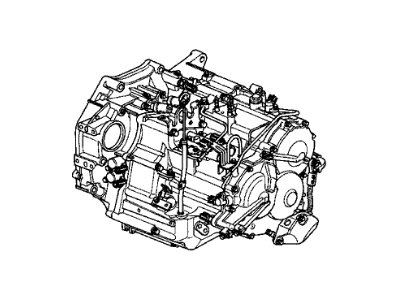

Acura TL Transmission Assembly

Part Number: 20021-RK3-000$4142.72 MSRP: $6278.11You Save: $2135.39 (35%)Ships in 1-2 Business DaysAcura TL Transmission Assembly (At)

Part Number: 20021-RDH-000$2678.41 MSRP: $4059.01You Save: $1380.60 (35%)Ships in 1-2 Business DaysAcura TL Transmission Assembly (At)

Part Number: 20021-RDG-020$820.41 MSRP: $1243.30You Save: $422.89 (35%)Ships in 1-2 Business DaysAcura TL Transmission Assembly (At)

Part Number: 20021-RDG-A52$3187.32 MSRP: $4830.23You Save: $1642.91 (35%)Ships in 1-2 Business DaysAcura TL Transmission Assembly

Part Number: 20011-RK6-M81$10448.94 MSRP: $16124.90You Save: $5675.96 (36%)Ships in 1-2 Business Days

| Page 1 of 2 |Next >

1-20 of 23 Results

Acura TL Transmission Assembly

We provide a broad range of OEM Acura TL Transmission Assembly at unbeatable prices on our website. For your OEM parts, You can count on the guaranteed quality, manufacturer's warranty, outstanding customer service, and prompt delivery. We look forward to your visit.

Acura TL Transmission Assembly Parts Questions & Experts Answers

- Q: Is overhauling a manual transaxle a challenging task for a do-it-yourselfer on Acura TL?A:Overhauling a manual transaxle is a challenging task for a do-it-yourselfer, requiring the disassembly and reassembly of numerous small parts, along with precise measurement of clearances that may need adjustment using select-fit spacers and snap-rings. While a competent individual can remove and install a transaxle, the overhaul process is best left to a repair shop, as the time and expense often surpass the cost of a rebuilt unit, which may be available through dealer parts departments and auto parts stores. An inexperienced mechanic can successfully rebuild a transaxle if equipped with the necessary special tools and approaches the job methodically to avoid overlooking any details. Essential tools for the overhaul include internal and external snap-ring pliers, a bearing puller, a slide hammer, a set of pin punches, a dial indicator, and possibly a hydraulic press, along with a sturdy workbench and a vise or transaxle stand. Careful documentation during disassembly is crucial, noting the arrangement and securing methods of each part to facilitate reassembly. Additionally, having an understanding of the malfunctioning area of the transaxle can simplify the examination and replacement of components, as certain issues are often linked to specific regions within the transaxle.

Related Acura TL Parts

Browse by Year

2014 Transmission Assembly 2013 Transmission Assembly 2012 Transmission Assembly 2011 Transmission Assembly 2010 Transmission Assembly 2009 Transmission Assembly 2008 Transmission Assembly 2007 Transmission Assembly 2006 Transmission Assembly 2005 Transmission Assembly 2004 Transmission Assembly 2003 Transmission Assembly 2002 Transmission Assembly 2001 Transmission Assembly 2000 Transmission Assembly 1999 Transmission Assembly 1998 Transmission Assembly 1997 Transmission Assembly 1996 Transmission Assembly 1995 Transmission Assembly