×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Acura Parts

- Acura Accessories

My Garage

My Account

Cart

Genuine Acura MDX Water Pump

H2O Pump- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Water Pumps found

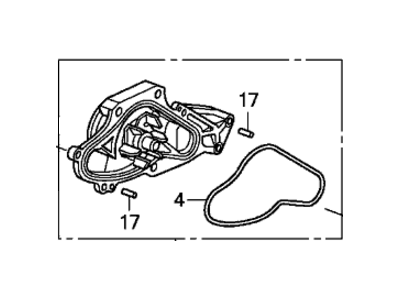

Acura MDX Water Pump (Yamada)

Part Number: 19200-RDV-J01$132.26 MSRP: $269.83You Save: $137.57 (51%)

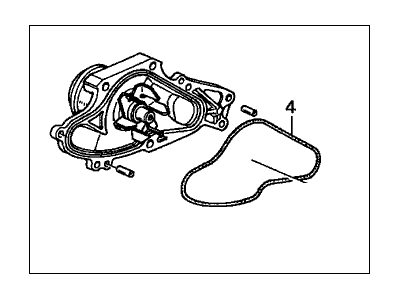

Acura MDX Water Pump (Yamada)

Part Number: 19200-P8A-A02$254.59 MSRP: $363.60You Save: $109.01 (30%)Ships in 1-2 Business DaysAcura MDX Water Pump

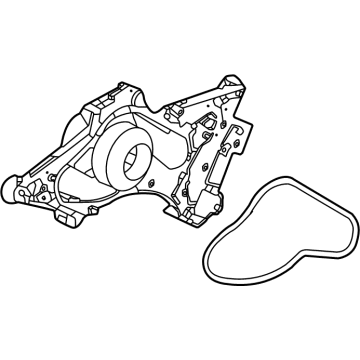

Part Number: 19200-6S9-A01$228.64 MSRP: $326.53You Save: $97.89 (30%)Ships in 1-3 Business DaysAcura MDX Water Pump Assembly

Part Number: 79960-TRX-A01$389.51 MSRP: $556.28You Save: $166.77 (30%)Ships in 1-3 Business Days

Acura MDX Water Pump

We provide a broad range of OEM Acura MDX Water Pump at unbeatable prices on our website. For your OEM parts, You can count on the guaranteed quality, manufacturer's warranty, outstanding customer service, and prompt delivery. We look forward to your visit.

Acura MDX Water Pump Parts Questions & Experts Answers

- Q: How to replace a water pump in a Acura MDX?A:Disconnect the cable from the negative battery terminal. Drain the cooling system and if the coolant is relatively new or in good condition, save it and reuse it. Remove the drive belts, followed by the timing belt, timing belt tensioner, and adjuster assembly. Take out the mounting bolts and detach the water pump from the engine. Clean the bolt threads and the threaded holes in the engine to eliminate corrosion and sealant. Compare the new pump with the old one to ensure they are identical. Remove all traces of sealant or O-ring from the engine mating surface. Clean the engine and new water pump mating surfaces with lacquer thinner or acetone. Apply a thin layer of RTV sealant to the O-ring groove of the new pump, and carefully set a new O-ring in the groove. Attach the pump to the engine and thread the bolts into the holes finger tight. Apply a small amount of RTV sealant on the bolt threads, ensuring any dowel pins are in their original locations. Tighten the bolts, reinstall all parts removed for pump access, and reconnect the battery. Finally, refill and bleed the cooling system, check the drive belt tension, run the engine, and ensure there are no leaks.

Related Acura MDX Parts

Browse by Year

2026 Water Pump 2025 Water Pump 2024 Water Pump 2023 Water Pump 2022 Water Pump 2020 Water Pump 2019 Water Pump 2018 Water Pump 2017 Water Pump 2016 Water Pump 2015 Water Pump 2014 Water Pump 2013 Water Pump 2012 Water Pump 2011 Water Pump 2010 Water Pump 2009 Water Pump 2008 Water Pump 2007 Water Pump 2006 Water Pump 2005 Water Pump 2004 Water Pump 2003 Water Pump 2002 Water Pump 2001 Water Pump