×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Acura Parts

- Acura Accessories

My Garage

My Account

Cart

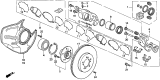

Genuine Acura TL Brake Pad Set

Disc Brake Pad Set- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

14 Brake Pad Sets found

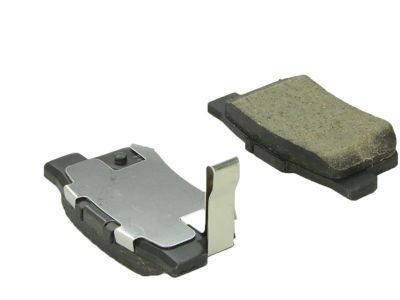

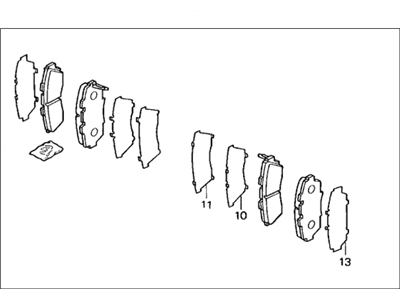

Acura TL Rear Disc Brake pad Set

Part Number: 43022-SEP-C01$65.53 MSRP: $91.40You Save: $25.87 (29%)Ships in 1-3 Business Days

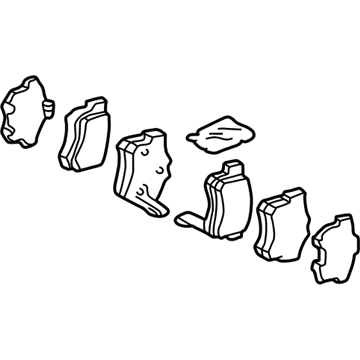

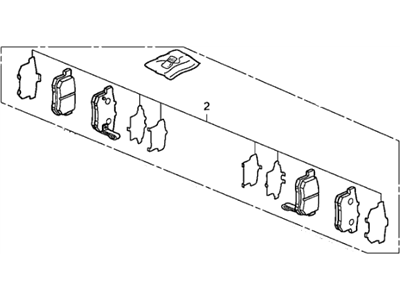

Acura TL Front Disc Brake pad Set (17In,28T)

Part Number: 45022-SJC-A02$79.75 MSRP: $111.88You Save: $32.13 (29%)Ships in 1-3 Business Days

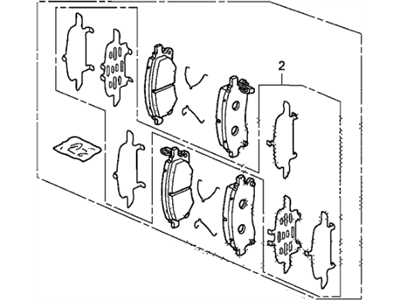

Acura TL Front Disc Brake pad Set

Part Number: 45022-SEP-A11$78.48 MSRP: $110.10You Save: $31.62 (29%)Ships in 1-3 Business Days

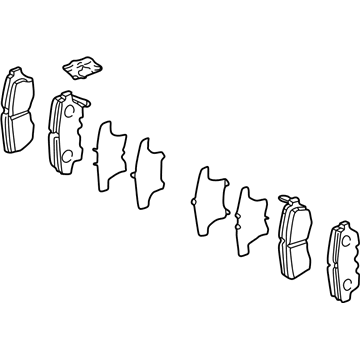

Acura TL Front Disc Brake pads

Part Number: 45022-SEP-A61$96.68 MSRP: $135.63You Save: $38.95 (29%)Ships in 1-2 Business Days

Acura TL Rear Acura Disc Brake pad Set

Part Number: 43022-SP0-030$65.53 MSRP: $91.40You Save: $25.87 (29%)Ships in 1-2 Business Days

Acura TL Front Disc Brake pad Set

Part Number: 45022-SJC-A01$79.75 MSRP: $111.88You Save: $32.13 (29%)

Acura TL Front Disc Brake pad Set(17Cl-1)

Part Number: 45022-S0K-A12$78.48 MSRP: $110.10You Save: $31.62 (29%)Ships in 1-2 Business Days

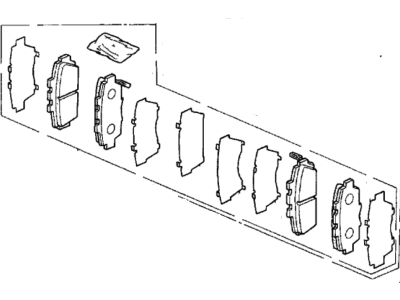

Acura TL Front Disc Brake pad Set

Part Number: 45022-SEP-A10$78.48 MSRP: $110.10You Save: $31.62 (29%)Ships in 1 Business Day

Acura TL Front Disc Brake pad Set

Part Number: 45022-SEP-A60$96.68 MSRP: $135.63You Save: $38.95 (29%)Ships in 1 Business Day

Acura TL Front Disc Brake pad Set

Part Number: 45022-S47-020$71.87 MSRP: $100.83You Save: $28.96 (29%)Ships in 1-3 Business DaysAcura TL Rear Disc Brake pad Set

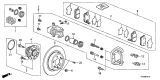

Part Number: 43022-TK4-A01$74.65 MSRP: $104.73You Save: $30.08 (29%)Ships in 1-3 Business DaysAcura TL Rear Disc Brake pad Set

Part Number: 43022-TK4-A00$74.65 MSRP: $104.73You Save: $30.08 (29%)Acura TL Front Disc Brake pad Kit

Part Number: 45022-SM5-525$71.87 MSRP: $100.83You Save: $28.96 (29%)Ships in 1-3 Business DaysAcura TL Rear Disc Brake pad Set (9Clp-1)

Part Number: 43022-SV4-A23$71.52 MSRP: $99.75You Save: $28.23 (29%)Ships in 1-3 Business Days

Acura TL Brake Pad Set

We provide a broad range of OEM Acura TL Brake Pad Set at unbeatable prices on our website. For your OEM parts, You can count on the guaranteed quality, manufacturer's warranty, outstanding customer service, and prompt delivery. We look forward to your visit.

Acura TL Brake Pad Set Parts Questions & Experts Answers

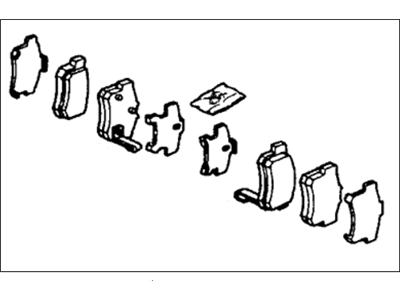

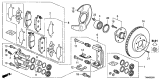

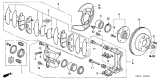

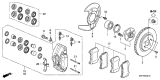

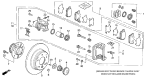

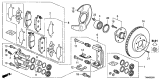

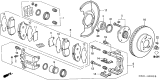

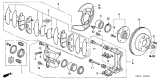

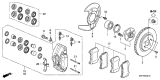

- Q: How do you replace brake pads and ensure proper brake function on Acura TL?A:Remove the cap from the brake fluid reservoir, loosen the wheel lug nuts, raise the vehicle, and support it securely on jack stands. Remove the front or rear wheels, working on one brake assembly at a time, using the assembled brake for reference if necessary. Inspect the Brake Disc carefully; if machining is necessary, remove the disc to access the calipers and pads. For floating calipers, push the piston back into the bore using a C-clamp to create room for new brake pads, ensuring the master cylinder fluid does not overflow. Follow the illustrations for the pad replacement procedure, installing the new pads in order. For fixed calipers, locate and remove the pad pins and cross-spring, noting their direction for reinstallation. Use needle-nose pliers to pull the inboard brake pad from the caliper, then push the caliper pistons into the bores while managing the brake fluid level. Prepare each new brake pad with a small amount of copper-based brake paste on the edges, position the new inboard pad, and repeat the process for the outboard pad, ensuring the wear indicator is correctly oriented. Install the pad pins and cross-spring, then install the wheel and lug nuts, lower the vehicle, and tighten the lug nuts to the specified torque. Before moving the vehicle, apply and release the brake pedal several times to ensure proper contact between the pads and brake discs, and check the brake fluid level, adding fluid if necessary, while testing the brakes in a safe area before driving in traffic.

Related Acura TL Parts

Browse by Year

2014 Brake Pad Set 2013 Brake Pad Set 2012 Brake Pad Set 2011 Brake Pad Set 2010 Brake Pad Set 2009 Brake Pad Set 2008 Brake Pad Set 2007 Brake Pad Set 2006 Brake Pad Set 2005 Brake Pad Set 2004 Brake Pad Set 2003 Brake Pad Set 2002 Brake Pad Set 2001 Brake Pad Set 2000 Brake Pad Set 1999 Brake Pad Set 1998 Brake Pad Set 1997 Brake Pad Set 1996 Brake Pad Set 1995 Brake Pad Set