×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Acura Parts

- Acura Accessories

My Garage

My Account

Cart

Genuine Acura TL Canister Purge Valve

Vapor Canister Purge Valve EVAP- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

14 Canister Purge Valves found

Acura TL Vapor Canister Purge Solenoid Valve

Part Number: 36162-RDV-J01$189.81 MSRP: $271.08You Save: $81.27 (30%)Ships in 1-3 Business Days

Acura TL Purge Control Solenoid Valve Assembly

Part Number: 36162-RMX-A01$150.11 MSRP: $214.38You Save: $64.27 (30%)

Acura TL Vapor Canister Purge Valve

Part Number: 17310-S0X-A02$86.24 MSRP: $120.98You Save: $34.74 (29%)Ships in 1-3 Business Days

Acura TL Vapor Canister Purge Solenoid

Part Number: 36160-P8E-A51$97.82 MSRP: $137.23You Save: $39.41 (29%)Ships in 1 Business Day

Acura TL Vapor Canister Valve (Made In Mexico)

Part Number: 17310-S84-L31$98.84 MSRP: $138.67You Save: $39.83 (29%)Ships in 1-3 Business Days

Acura TL Purge Control Solenoid Stay

Part Number: 36163-R70-A00$196.29 MSRP: $280.33You Save: $84.04 (30%)Ships in 1-3 Business DaysAcura TL Canister Vent Shut Valve

Part Number: 17310-SV4-L32$271.36 MSRP: $387.55You Save: $116.19 (30%)Ships in 1-3 Business DaysAcura TL Purge Control Solenoid Valve Assembly

Part Number: 36160-P8C-A01$65.03 MSRP: $104.78You Save: $39.75 (38%)Ships in 1-2 Business Days

Acura TL Original Canister Vent Shut Valve Fit

Part Number: 17311-TA0-A01$66.29 MSRP: $92.45You Save: $26.16 (29%)

Acura TL Canister Purge Valve

We provide a broad range of OEM Acura TL Canister Purge Valve at unbeatable prices on our website. For your OEM parts, You can count on the guaranteed quality, manufacturer's warranty, outstanding customer service, and prompt delivery. We look forward to your visit.

Acura TL Canister Purge Valve Parts Questions & Experts Answers

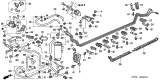

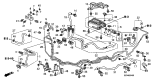

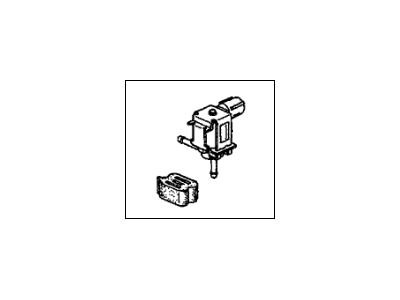

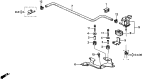

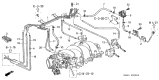

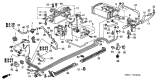

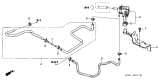

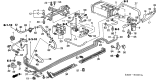

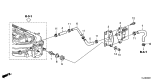

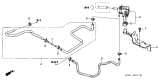

- Q: What is the purpose and function of the Evaporative Emissions Control (EVAP) system,Canister Purge Valve and Canister on Acura TL?A:The Evaporative Emissions Control (EVAP) system is designed to keep from escaping into the atmosphere fuel system vapors rich in unburned hydrocarbons. When it's warm outside, vapor from the fuel tank expands and is carried via various valves into the EVAP canister to temporarily store until the vehicle is run. Only under ideal conditions does the Powertrain Control Module (PCM) open the canister purge valve and entry vapors can be mixed with incoming air into the intake manifold where they're combusted in the combustion chambers. These vapors are stored in the EVAP canister, which is typically maintenance free, and contains activated charcoal. Included among the key components are the canister filter, canister vent shut valve, two way valve, the bypass solenoid valve and the fuel tank pressure sensor, all of which provide information and control specialty over vapor flow. When something is wrong, fuel smells common and, most of the time, engine performance suffers too, so you need to know what it is, so check hoses and connections for damage and leaks. The EVAP canister purge valve and the canister assembly can be accessed to perform repairs when the vehicle is raised, while the fuel tank pressure sensor and vent shut valve provide more involved disconnection and installation of various components. Hoses should be properly labeled and new O rings used when reassembling to maintain system integrity.

Related Acura TL Parts

Browse by Year

2014 Canister Purge Valve 2013 Canister Purge Valve 2012 Canister Purge Valve 2011 Canister Purge Valve 2010 Canister Purge Valve 2009 Canister Purge Valve 2008 Canister Purge Valve 2007 Canister Purge Valve 2006 Canister Purge Valve 2005 Canister Purge Valve 2004 Canister Purge Valve 2003 Canister Purge Valve 2002 Canister Purge Valve 2001 Canister Purge Valve 2000 Canister Purge Valve 1999 Canister Purge Valve 1998 Canister Purge Valve 1997 Canister Purge Valve 1996 Canister Purge Valve 1995 Canister Purge Valve