×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Acura Parts

- Acura Accessories

My Garage

My Account

Cart

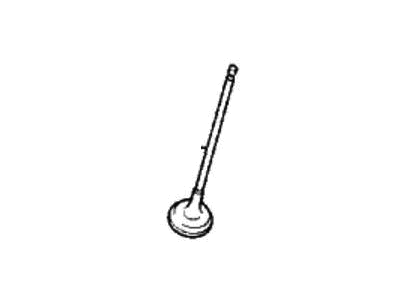

Genuine Acura TL Intake Valve

Engine Intake Valve- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

6 Intake Valves found

Acura TL Intake Valve

Part Number: 14711-RYE-A00$7.12 MSRP: $9.93You Save: $2.81 (29%)Ships in 1-2 Business Days

Acura TL Intake Valve

Part Number: 14711-P8E-A00$19.83 MSRP: $27.65You Save: $7.82 (29%)Ships in 1-3 Business Days

Acura TL Valve, In.

Part Number: 14711-PGE-A00$31.18 MSRP: $43.48You Save: $12.30 (29%)Ships in 1-3 Business Days

Acura TL Intake Valve

We provide a broad range of OEM Acura TL Intake Valve at unbeatable prices on our website. For your OEM parts, You can count on the guaranteed quality, manufacturer's warranty, outstanding customer service, and prompt delivery. We look forward to your visit.

Acura TL Intake Valve Parts Questions & Experts Answers

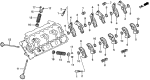

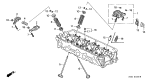

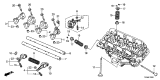

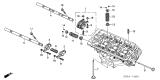

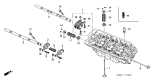

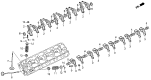

- Q: How to check and adjust valve clearance on Acura TL?A:The valve clearance generally does not need adjustment unless valve train components have been replaced, a valve job has been performed, or if the valves are noisy. The simplest check for proper valve adjustment is to listen carefully to the engine running with the hood open; if the valve train is noisy, adjustment is necessary. The valve clearance must be checked and adjusted with the engine cold. To begin, remove the Valve Covers and rotate the crankshaft clockwise to position the number one piston at TDC, ensuring the pointer on the front timing belt cover aligns with the sprocket mark. In this position, adjust the valves for cylinder number one, which has four valves. Starting with the intake valve, insert a feeler gauge of the correct thickness between the valve stem and the Rocker Arm; you should feel a slight drag when withdrawing it. If there's no drag or a heavy drag, loosen the adjuster nut and back off the adjuster screw, then carefully tighten the adjuster screw until a slight drag is felt on the feeler gauge. Hold the adjuster screw with a screwdriver to prevent it from turning while tightening the locknut, and recheck the clearance to ensure it hasn't changed. Repeat this process for the other intake valve and then for the two exhaust valves. Next, rotate the crankshaft pulley clockwise until the number "4" on the camshaft sprocket aligns with the pointer on the timing belt cover to check and adjust the number four cylinder valves. Continue rotating the crankshaft pulley clockwise until the number "2" cylinder is at TDC to check and adjust the number two cylinder valves, then proceed to the number five cylinder valves when the number "5" shows at the camshaft cover, followed by the number three cylinder valves when the number "3" shows, and finally the number six cylinder valves when the number "6" shows at the camshaft cover.

Related Acura TL Parts

Browse by Year

2014 Intake Valve 2013 Intake Valve 2012 Intake Valve 2011 Intake Valve 2010 Intake Valve 2009 Intake Valve 2008 Intake Valve 2007 Intake Valve 2006 Intake Valve 2005 Intake Valve 2004 Intake Valve 2003 Intake Valve 2002 Intake Valve 2001 Intake Valve 2000 Intake Valve 1999 Intake Valve 1998 Intake Valve 1997 Intake Valve 1996 Intake Valve 1995 Intake Valve