×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Acura Parts

- Acura Accessories

My Garage

My Account

Cart

Genuine Acura TL Oxygen Sensor

Oxygen O2 Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

28 Oxygen Sensors found

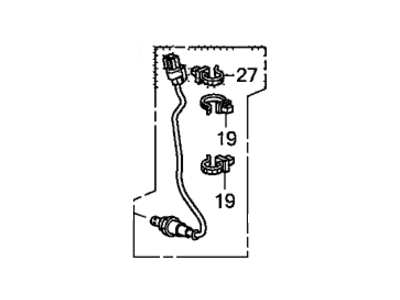

Acura TL Front Laf Sensor

Part Number: 36531-RDM-A01$253.08 MSRP: $361.43You Save: $108.35 (30%)Ships in 1-3 Business Days

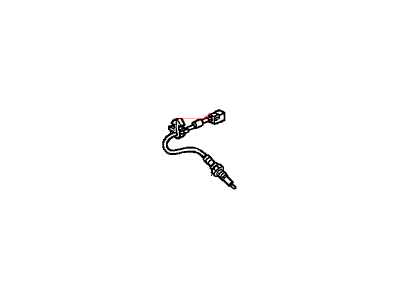

Acura TL Air Fuel Sensor

Part Number: 36531-RCA-A02$253.08 MSRP: $361.43You Save: $108.35 (30%)Ships in 1-3 Business Days

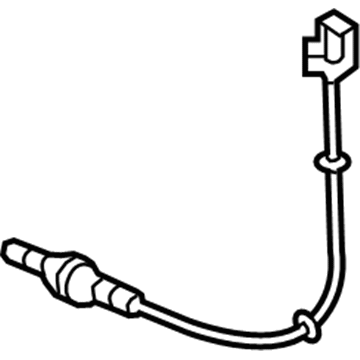

Acura TL Front Secondary Oxygen Sensor

Part Number: 36532-RYE-A01$142.99 MSRP: $201.97You Save: $58.98 (30%)Ships in 1-3 Business Days

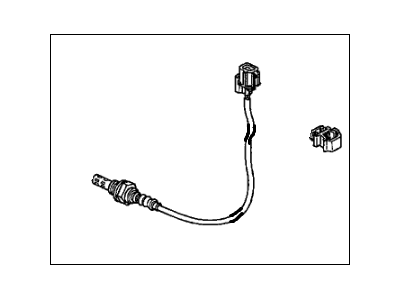

Acura TL Rear Oxygen Sensor

Part Number: 36542-R70-A01$142.99 MSRP: $201.97You Save: $58.98 (30%)Ships in 1-3 Business Days

Acura TL Rear Laf Sensor

Part Number: 36541-R70-A02$185.10 MSRP: $264.35You Save: $79.25 (30%)Ships in 1-3 Business Days

Acura TL Oxygen Sensor

Part Number: 36531-P8E-A11$227.02 MSRP: $324.22You Save: $97.20 (30%)Ships in 1-3 Business Days

Acura TL Front Oxygen Sensor

Part Number: 36532-R70-A01$142.99 MSRP: $201.97You Save: $58.98 (30%)Ships in 1-2 Business Days

Acura TL Rear Secondary Oxygen Sensor

Part Number: 36542-RDA-A01$142.99 MSRP: $201.97You Save: $58.98 (30%)Ships in 1-3 Business Days

Acura TL Front Secondary Oxygen Sensor

Part Number: 36532-RDB-A01$142.99 MSRP: $201.97You Save: $58.98 (30%)Ships in 1-3 Business Days

Acura TL Rear Oxygen Sensor

Part Number: 36532-P8D-J01$161.55 MSRP: $228.18You Save: $66.63 (30%)Ships in 1-2 Business DaysAcura TL Oxygen Air Sensor

Part Number: 36531-R70-A02$190.10 MSRP: $271.50You Save: $81.40 (30%)Ships in 1-3 Business DaysAcura TL Front Oxygen Sensor

Part Number: 36532-RYE-A11$142.99 MSRP: $201.97You Save: $58.98 (30%)Ships in 1-3 Business DaysAcura TL Rear Oxygen Sensor

Part Number: 36532-P8C-L21$217.66 MSRP: $310.85You Save: $93.19 (30%)Ships in 1-3 Business DaysAcura TL Rear Laf Sensor

Part Number: 36541-R70-A01$185.10 MSRP: $264.35You Save: $79.25 (30%)Ships in 1-3 Business DaysAcura TL Front Lower Oxygen Sensor

Part Number: 36532-RK2-A01$142.99 MSRP: $201.97You Save: $58.98 (30%)Ships in 1-3 Business DaysAcura TL Secondary Oxygen Sensor

Part Number: 36532-RCA-A51$103.49 MSRP: $145.18You Save: $41.69 (29%)Ships in 1-3 Business DaysAcura TL Rear Secondary Oxygen Sensor

Part Number: 36542-RKB-004$197.77 MSRP: $282.45You Save: $84.68 (30%)Ships in 1-3 Business DaysAcura TL Front Oxygen Sensor

Part Number: 36532-RKB-004$142.99 MSRP: $201.97You Save: $58.98 (30%)Ships in 1-3 Business Days

| Page 1 of 2 |Next >

1-20 of 28 Results

Acura TL Oxygen Sensor

We provide a broad range of OEM Acura TL Oxygen Sensor at unbeatable prices on our website. For your OEM parts, You can count on the guaranteed quality, manufacturer's warranty, outstanding customer service, and prompt delivery. We look forward to your visit.

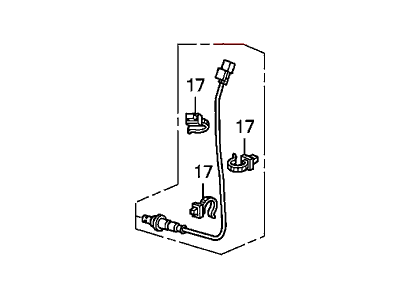

Acura TL Oxygen Sensor Parts Questions & Experts Answers

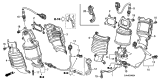

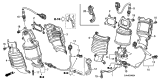

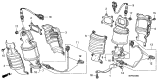

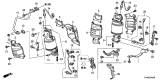

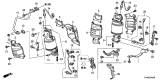

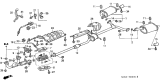

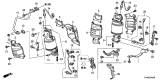

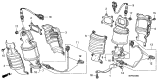

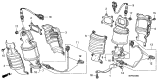

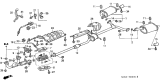

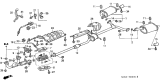

- Q: What should be noted when servicing an oxygen sensor on Acura TL?A:When servicing an oxygen sensor, it is important to note that due to its installation in the exhaust manifold or pipe, it may be difficult to loosen when the engine is cold; therefore, starting and running the engine briefly can help. Care should be taken to avoid damaging the permanently attached pigtail and electrical connector, as any damage will render the sensor useless. Keep contaminants away from the electrical connector and the louvered end, and do not use cleaning solvents on the sensor, which is delicate and should not be dropped or handled roughly. Ensure the silicone boot is correctly positioned to prevent melting. For replacement, raise the vehicle securely on jackstands. In 2003 and earlier models, the upstream sensor is located behind the exhaust pipe "Y" junction and ahead of the Catalytic Converter, while the downstream sensor is screwed into the catalyst. Disconnect the electrical connector for the upstream sensor, remove it using a wrench, and apply anti-seize compound if reinstalling the old sensor; new sensors do not require this. The installation follows the reverse order, ensuring proper torque. For 2004 and later models, the upstream sensors are at the cylinder heads above the warm-up catalysts. After removing the engine cover, disconnect the electrical connector, use an oxygen sensor socket for removal, and apply anti-seize compound if reinstalling the old sensor. The installation is again the reverse of removal. For downstream sensors in these models, raise the vehicle, remove the engine under cover, locate and disconnect the electrical connector, and follow the same procedures for removal and installation, ensuring proper torque.

Related Acura TL Parts

Browse by Year

2014 Oxygen Sensor 2013 Oxygen Sensor 2012 Oxygen Sensor 2011 Oxygen Sensor 2010 Oxygen Sensor 2009 Oxygen Sensor 2008 Oxygen Sensor 2007 Oxygen Sensor 2006 Oxygen Sensor 2005 Oxygen Sensor 2004 Oxygen Sensor 2003 Oxygen Sensor 2002 Oxygen Sensor 2001 Oxygen Sensor 2000 Oxygen Sensor 1999 Oxygen Sensor 1998 Oxygen Sensor 1997 Oxygen Sensor 1996 Oxygen Sensor 1995 Oxygen Sensor