×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Acura Parts

- Acura Accessories

My Garage

My Account

Cart

Genuine Acura Integra Canister Purge Valve

Vapor Canister Purge Valve EVAP- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

15 Canister Purge Valves found

Acura Integra Vapor Canister Purge Valve

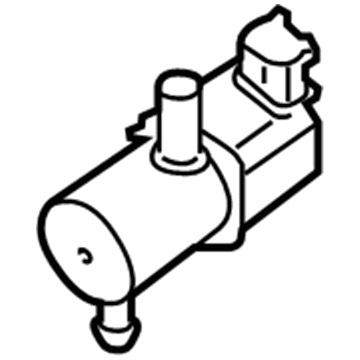

Part Number: 17310-S0X-A02$86.24 MSRP: $120.98You Save: $34.74 (29%)Ships in 1-3 Business DaysAcura Integra Vapor Canister-Purge Control Valve

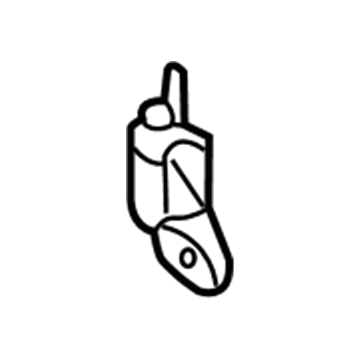

Part Number: 17310-TBA-A01$66.29 MSRP: $92.45You Save: $26.16 (29%)Acura Integra Canister Vent Shut Valve

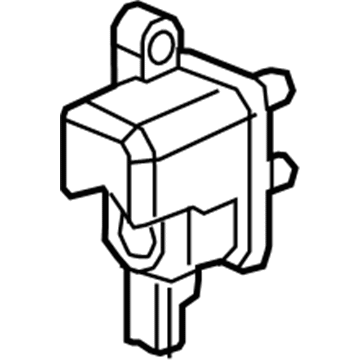

Part Number: 17310-SV4-L32$271.36 MSRP: $387.55You Save: $116.19 (30%)Ships in 1-3 Business DaysAcura Integra Purge Control Solenoid Valve Assembly

Part Number: 36162-5R7-A01$174.27 MSRP: $246.15You Save: $71.88 (30%)Ships in 1-3 Business DaysAcura Integra Valve, Purge Control Solenoid

Part Number: 36162-5AA-A01$54.90 MSRP: $76.57You Save: $21.67 (29%)Ships in 1-3 Business Days

Acura Integra Canister Purge Valve

We provide a broad range of OEM Acura Integra Canister Purge Valve at unbeatable prices on our website. For your OEM parts, You can count on the guaranteed quality, manufacturer's warranty, outstanding customer service, and prompt delivery. We look forward to your visit.

Acura Integra Canister Purge Valve Parts Questions & Experts Answers

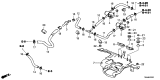

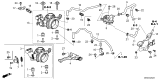

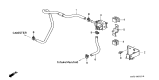

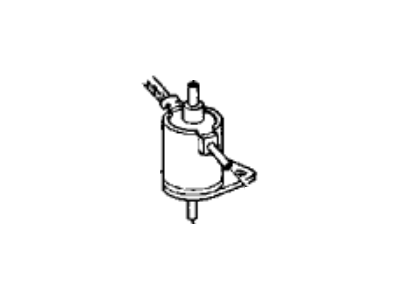

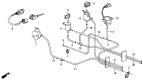

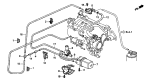

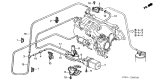

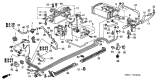

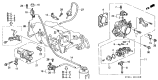

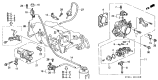

- Q: What is the function and operation of the fuel evaporative emissions control system and Canister Purge Valve on Acura Integra?A:The fuel evaporative emissions control system absorbs fuel vapors and releases them into the engine intake during operation, where they mix with the incoming air-fuel mixture. Each system uses a canister filled with activated charcoal to absorb these vapors, though the methods of control can vary significantly. A fuel filler cap equipped with a two-way valve vents vapors to the atmosphere if the system fails, while another two-way valve on the fuel tank regulates vapor flow based on pressure changes. Fuel vapor travels through vent hoses to the charcoal canister, where it is stored until the engine reaches a preset temperature, at which point a purge cut-off solenoid valve closes, allowing intake manifold vacuum to draw vapors from the canister. Checking the system is typically beyond the average home mechanic's scope, but the EVAP system is covered by a federally mandated extended warranty. The most common issue is a disconnected or damaged hose, which should be checked against the vacuum hose routing diagram. The purge control solenoid allows vapor purging when the engine is warm and cuts off vacuum when cold; testing involves checking for vacuum presence at the hose end and ensuring the solenoid opens and closes correctly when battery voltage is applied. The two-way valve should stabilize at specific vacuum and pressure levels during testing, and if it does not, it should be replaced. To check for a canister vent shutoff valve, look for a two-wire connector on top of the canister, and if present, test its functionality by applying vacuum and checking for leaks after disconnecting the electrical connector.

Related Acura Integra Parts

Browse by Year

2026 Canister Purge Valve 2025 Canister Purge Valve 2024 Canister Purge Valve 2023 Canister Purge Valve 2001 Canister Purge Valve 2000 Canister Purge Valve 1999 Canister Purge Valve 1998 Canister Purge Valve 1997 Canister Purge Valve 1996 Canister Purge Valve 1995 Canister Purge Valve 1994 Canister Purge Valve 1993 Canister Purge Valve 1992 Canister Purge Valve 1991 Canister Purge Valve 1990 Canister Purge Valve 1989 Canister Purge Valve 1988 Canister Purge Valve 1987 Canister Purge Valve 1986 Canister Purge Valve