×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Acura Parts

- Acura Accessories

My Garage

My Account

Cart

Genuine Acura Integra Headlight

Headlamp- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

24 Headlights found

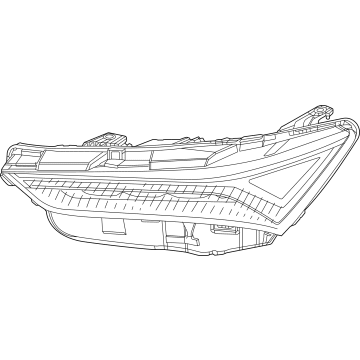

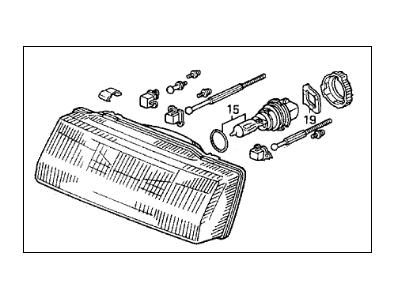

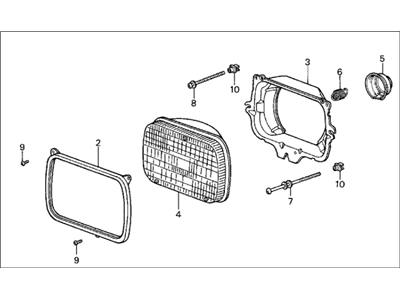

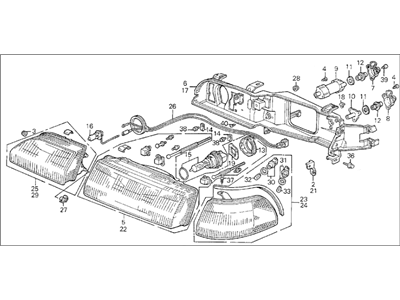

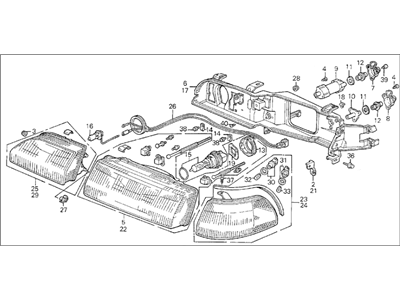

Acura Integra Right Headlight Assembly

Part Number: 33100-ST7-A01$411.78 MSRP: $588.08You Save: $176.30 (30%)Ships in 1-3 Business DaysAcura Integra Headlight Assembly , Left

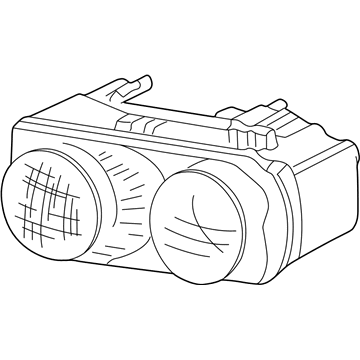

Part Number: 33150-3S5-A02$874.02 MSRP: $1248.25You Save: $374.23 (30%)Ships in 1-2 Business DaysAcura Integra Headlight Assembly , Right

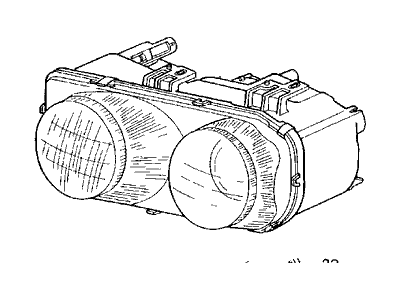

Part Number: 33100-3S5-A02$874.02 MSRP: $1248.25You Save: $374.23 (30%)Ships in 1-2 Business DaysAcura Integra Headlight Assembly , Right

Part Number: 33100-3S5-A01$874.02 MSRP: $1248.25You Save: $374.23 (30%)Ships in 1-3 Business Days

| Page 1 of 2 |Next >

1-20 of 24 Results

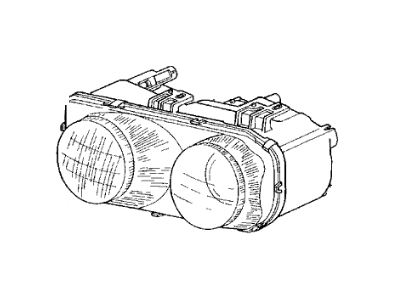

Acura Integra Headlight

We provide a broad range of OEM Acura Integra Headlight at unbeatable prices on our website. For your OEM parts, You can count on the guaranteed quality, manufacturer's warranty, outstanding customer service, and prompt delivery. We look forward to your visit.

Acura Integra Headlight Parts Questions & Experts Answers

- Q: How should headlights be aimed correctly to avoid blinding oncoming drivers and ensure safety on Acura Integra?A:The headlights must be aimed correctly to avoid blinding oncoming drivers, which can lead to serious accidents or impair visibility. It is important to check the aim every 12 months and whenever a new headlight is installed or front-end body work is done. The following procedure provides a temporary adjustment until a professional can perform a proper alignment. Headlights feature spring-loaded adjusting screws for vertical and horizontal movement. One simple method for adjustment involves using a blank wall and a level floor. Begin by positioning masking tape vertically on the wall to align with the vehicle's centerline and the centerlines of both headlights, then add a horizontal tape line for reference. The vehicle should be parked 25 feet from the wall, level, with a half-full gas tank and no heavy load. For low beam adjustment, set the high-intensity zone two inches below the horizontal line and two inches to the side of the headlight vertical line, away from oncoming traffic, using the vertical adjusting screw for height and the horizontal screw for left or right movement. With high beams on, the high-intensity zone should be centered just below the horizontal line. It may not be possible to achieve perfect alignment for both high and low beams, so prioritize low beams for safety. Have the headlights professionally adjusted at the earliest opportunity.