×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Acura Parts

- Acura Accessories

My Garage

My Account

Cart

Genuine Acura Integra Oxygen Sensor

Oxygen O2 Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

19 Oxygen Sensors found

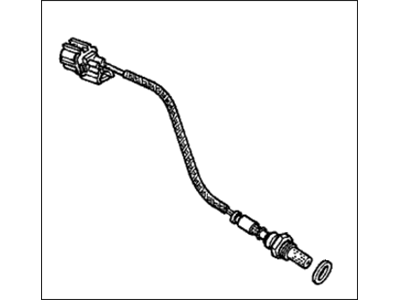

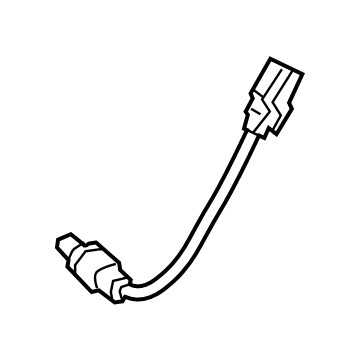

Acura Integra Sensor, Laf

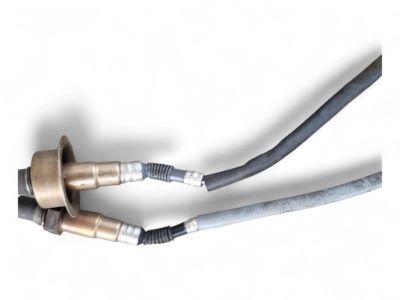

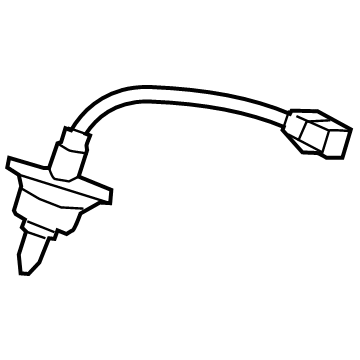

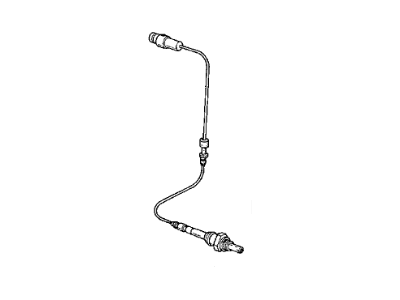

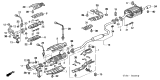

Part Number: 36531-66V-A01$142.38 MSRP: $201.10You Save: $58.72 (30%)Ships in 1-2 Business DaysAcura Integra Oxygen Sensor (Denso)

Part Number: 36531-PG7-661$166.95 MSRP: $235.81You Save: $68.86 (30%)Ships in 1-3 Business DaysAcura Integra Oxygen Sensor

Part Number: 36531-P06-A12$310.94 MSRP: $444.08You Save: $133.14 (30%)Ships in 1-3 Business DaysAcura Integra SENSOR, OXYGEN

Part Number: 36532-6VJ-A01$139.79 MSRP: $197.45You Save: $57.66 (30%)Ships in 1-2 Business DaysAcura Integra Sensor, Oxygen

Part Number: 36532-64A-A01$157.59 MSRP: $222.58You Save: $64.99 (30%)Ships in 1-3 Business DaysAcura Integra Sensor, Oxygen

Part Number: 36532-5BF-A01$149.68 MSRP: $211.42You Save: $61.74 (30%)Ships in 1-2 Business DaysAcura Integra SENSOR, LAF

Part Number: 36531-6VJ-A01$229.62 MSRP: $327.93You Save: $98.31 (30%)Ships in 1-2 Business DaysAcura Integra Sensor, Laf

Part Number: 36531-64A-A01$228.57 MSRP: $326.43You Save: $97.86 (30%)Ships in 1-3 Business Days

Acura Integra Oxygen Sensor

We provide a broad range of OEM Acura Integra Oxygen Sensor at unbeatable prices on our website. For your OEM parts, You can count on the guaranteed quality, manufacturer's warranty, outstanding customer service, and prompt delivery. We look forward to your visit.

Acura Integra Oxygen Sensor Parts Questions & Experts Answers

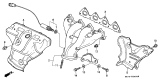

- Q: What is the function and importance of the oxygen sensor in emissions control on Acura Integra?A:The oxygen sensor, located in the exhaust manifold, monitors the oxygen content of the exhaust gas stream, producing a voltage output that varies from 0.1 volts (indicating a high oxygen, lean mixture) to 0.9 volts (indicating a low oxygen, rich mixture). The PCM continuously monitors this voltage to determine the oxygen-to-fuel ratio, adjusting the air/fuel mixture by controlling the pulse width of the fuel injectors, aiming for an ideal ratio of 14.7 parts air to 1 part fuel to minimize emissions and optimize Catalytic Converter efficiency. In 1996 and later models, two oxygen sensors are utilized; the primary sensor is positioned before or within the catalytic converter, while the secondary sensor is located after it, serving to monitor catalytic converter efficiency without influencing the air/fuel mixture. The oxygen sensor requires specific conditions for proper operation, including clean electrical connections, unrestricted air supply, appropriate operating temperature of around 600 degrees F, and the use of unleaded fuel. Special care is necessary during servicing to avoid damaging the sensor or its connections. Testing involves monitoring the voltage signal as the engine warms, with a healthy sensor fluctuating between 0.1 and 0.9 volts in closed loop mode, while the secondary sensor should stabilize around 0.3 to 0.6 volts. The heater's functionality can be checked with an ohmmeter, and proper supply voltage should be verified. If any tests indicate failure, the sensor should be replaced. When replacing the sensor, it is advisable to warm the engine to ease removal, disconnect the battery, and ensure the use of anti-seize compound on the threads to facilitate future removal. After installation, the electrical connector should be reattached, and a test drive should confirm that no trouble codes are present.

Related Acura Integra Parts

Browse by Year

2026 Oxygen Sensor 2025 Oxygen Sensor 2024 Oxygen Sensor 2023 Oxygen Sensor 2001 Oxygen Sensor 2000 Oxygen Sensor 1999 Oxygen Sensor 1998 Oxygen Sensor 1997 Oxygen Sensor 1996 Oxygen Sensor 1995 Oxygen Sensor 1994 Oxygen Sensor 1993 Oxygen Sensor 1992 Oxygen Sensor 1991 Oxygen Sensor 1990 Oxygen Sensor 1989 Oxygen Sensor 1988 Oxygen Sensor 1987 Oxygen Sensor 1986 Oxygen Sensor