×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Acura Parts

- Acura Accessories

My Garage

My Account

Cart

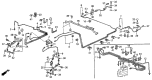

Genuine Acura Legend Brake Line

Brake Hose- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

29 Brake Lines found

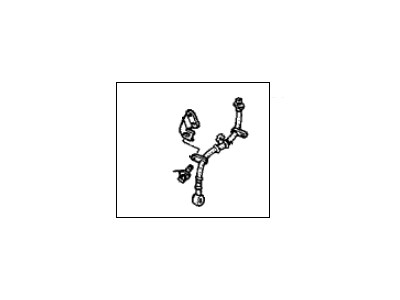

Acura Legend Hose Set,Left Rear Brake

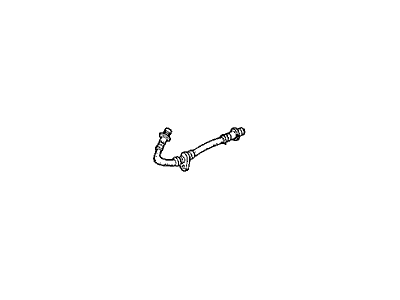

Part Number: 01468-SD4-010$5.09 MSRP: $40.98You Save: $35.89 (88%)Ships in 1-2 Business DaysAcura Legend Hose A, Rear Brake (Nichirin)

Part Number: 46430-SD4-033$21.26 MSRP: $30.37You Save: $9.11 (30%)Acura Legend Hose A, Rear Brake (Meiji)

Part Number: 46430-SD4-024$21.26 MSRP: $30.37You Save: $9.11 (30%)Acura Legend Hose A, Rear Brake (Nichirin)

Part Number: 46430-SD4-023$21.26 MSRP: $30.37You Save: $9.11 (30%)Acura Legend Hose A, Rear Brake (Meiji)

Part Number: 46430-SD4-014$21.26 MSRP: $30.37You Save: $9.11 (30%)Acura Legend Hose Set,Rear Front Brake

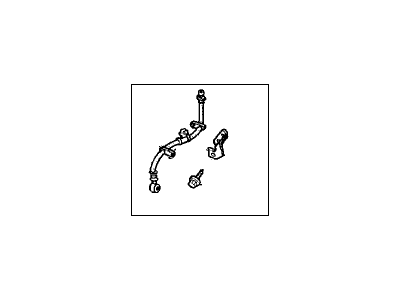

Part Number: 01464-SD4-020$57.46 MSRP: $82.07You Save: $24.61 (30%)Ships in 1-3 Business DaysAcura Legend Hose Set, Left, Front.Brake

Part Number: 01465-SD4-020$58.84 MSRP: $82.07You Save: $23.23 (29%)Ships in 1-3 Business Days

| Page 1 of 2 |Next >

1-20 of 29 Results

Acura Legend Brake Line

We provide a broad range of OEM Acura Legend Brake Line at unbeatable prices on our website. For your OEM parts, You can count on the guaranteed quality, manufacturer's warranty, outstanding customer service, and prompt delivery. We look forward to your visit.

Acura Legend Brake Line Parts Questions & Experts Answers

- Q: How often should you inspect the flexible hoses connecting the steel brake lines with the rear brakes and front calipers on Acura Legend?A:Inspect the flexible hoses that connect the steel brake lines to rear brakes and front calipers for cracks, chafing, leaks, blisters and more about every six months. If this is the case, replacement steel and flexible brake lines are widely available from dealer parts departments and auto parts stores; only use genuine steel lines or approved flexible brake hoses for replacements. If installing the brake line, make sure it leaves at least 0.75 inches (19 mm) between the line and parts that move or vibrate. To disconnect a hose and line, break loose the fitting of the hose to the brake line with a flare nut wrench, remove the clip and slide the hose out of the bracket. Normal wrenches are used on hose fittings when disconnecting two hoses, and ensure the hose fittings are not twisted or strained when the hoses are connected. Fixed brake lines are usually retained with clips, which should be fully removed prior to a fixed brake line being removed, and reinstalled or new clips if damaged, to support and minimize vibration which constantly leads to breakage. To replace brake lines, get the correct parts and never use copper tubing and buy steel brake lines from a dealer or an auto parts store. Make sure the steel line is well supported in the brackets with sufficient clearance of moving component. Install the master cylinder replacing it and close the bleeder valve if not already done then check the fluid levels in the master cylinder and add as necessary and bleed the brake system, then carefully test the brakes before taking the vehicle out in traffic.