×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Acura Parts

- Acura Accessories

My Garage

My Account

Cart

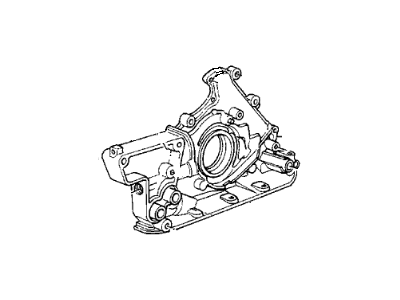

Genuine Acura Legend Oil Pump

Oil Fluid Pump- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

7 Oil Pumps found

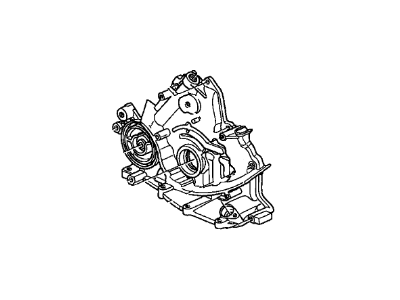

Acura Legend Oil Pump

We provide a broad range of OEM Acura Legend Oil Pump at unbeatable prices on our website. For your OEM parts, You can count on the guaranteed quality, manufacturer's warranty, outstanding customer service, and prompt delivery. We look forward to your visit.

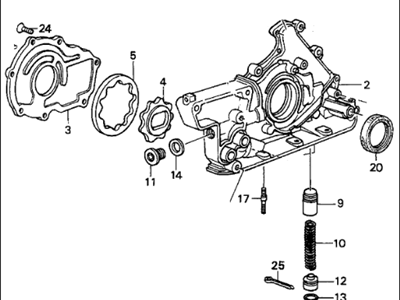

Acura Legend Oil Pump Parts Questions & Experts Answers

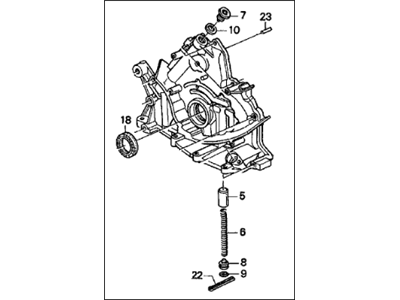

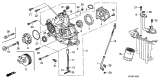

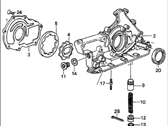

- Q: What Is the Correct Procedure for Removing and Reinstalling the Oil Pump on Acura Legend?A:To remove the oil cooler, start by taking off the Timing Belt and crankshaft sprocket while keeping the Engine Mount connected at the timing belt end for support; it's not necessary to completely remove the belt. Next, detach the Oil Pan and oil pickup screen, ensuring to remove the oil level sensor on LS models. Remove the bolts to detach the oil pump from the engine, using a screwdriver to pry carefully between the main bearing cap and the pump body if needed. Use a large Phillips screwdriver to take out the screws holding the body cover to the rear of the oil pump, then lift the cover off to inspect the pump rotors for any wear or damage, replacing the pump if necessary. Clean any old sealant from the pump body and engine block with a scraper, being cautious not to damage the aluminum. For installation, replace the old crankshaft oil seal and apply moly-base grease to the seal lip. Pack the pump cavity with petroleum jelly and install the cover, tightening the screws securely in a criss-cross pattern. Clean the gasket surfaces with acetone or lacquer thinner to remove all oil traces, then apply a bead of sealant to the oil pump flange and bolt, ensuring parts are assembled within five minutes to avoid reapplication. If the oil pass pipe was removed, position it for installation with a new seal. Engage the oil pump drive rotor with the crankshaft and slide the pump into place, then install the pump mounting bolts in their original locations, tightening them in a criss-cross pattern. Using a new O-ring, install the oil pickup screen and tighten the fasteners. Reinstall the remaining parts in reverse order, add oil, start the engine, and check for oil leaks and pressure, followed by rechecking the engine oil level.