×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Acura Parts

- Acura Accessories

My Garage

My Account

Cart

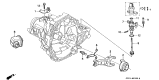

Genuine Acura Integra Clutch Fork

Release Fork- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

5 Clutch Forks found

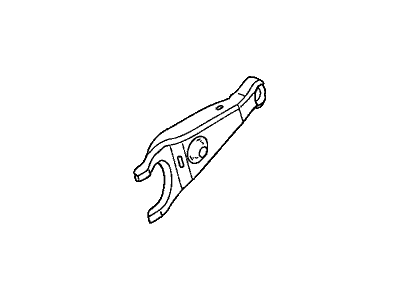

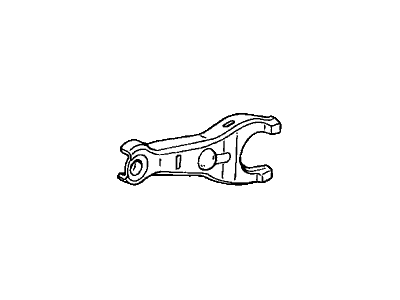

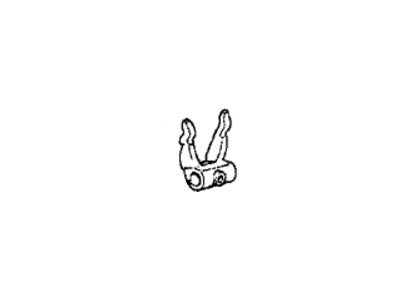

Acura Integra Clutch Release Fork

Part Number: 22821-PPP-000$132.20 MSRP: $188.80You Save: $56.60 (30%)

Acura Integra Clutch Release Fork

Part Number: 22821-P80-010$75.46 MSRP: $105.87You Save: $30.41 (29%)Ships in 1-3 Business Days

Acura Integra Clutch Fork

We provide a broad range of OEM Acura Integra Clutch Fork at unbeatable prices on our website. For your OEM parts, You can count on the guaranteed quality, manufacturer's warranty, outstanding customer service, and prompt delivery. We look forward to your visit.

Acura Integra Clutch Fork Parts Questions & Experts Answers

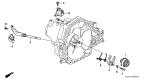

- Q: How to Inspect, Lubricate, and Replace the Clutch Release Bearing and Clutch Fork on Acura Integra?A:Unbolt the clutch release cylinder without disconnecting the fluid line and suspend it out of the way with a piece of wire. Remove the transaxle, then slide the release bearing off the input shaft, disengage the clutch fork retention spring from the ball stud, and remove the fork by reaching behind the Clutch Fork to disengage the retention spring before removing the Clutch Fork and sliding the bearing tangs. Hold the bearing by the outer race and rotate the inner race while applying pressure; if it doesn't turn smoothly or is noisy, replace the bearing/hub assembly with a new one. Wipe the bearing with a clean rag and inspect it for damage, wear, and cracks, as it is common practice to replace the bearing during a clutch job to reduce the risk of future failure. Avoid immersing the bearing in solvent since it is sealed for life, and also check the Clutch Fork for cracks and bends. Fill the inner groove of the release bearing with high-temperature grease and apply a light coat of the same grease to the transaxle input shaft splines and the input shaft bearing retainer. Lubricate the clutch fork ball socket, fork ends, and release cylinder pushrod socket with high-temperature grease. Attach the release bearing to the clutch fork, then slide the release bearing onto the transaxle input shaft front bearing retainer while passing the end of the clutch fork through the opening in the clutch housing, pushing the clutch fork onto the ball stud until it is firmly seated. Apply a light coat of high-temperature grease to the face of the release bearing where it contacts the pressure plate diaphragm fingers, and complete the installation by reversing the removal procedure.

Related Acura Integra Parts

Browse by Year

2026 Clutch Fork 2025 Clutch Fork 2024 Clutch Fork 2023 Clutch Fork 2001 Clutch Fork 2000 Clutch Fork 1999 Clutch Fork 1998 Clutch Fork 1997 Clutch Fork 1996 Clutch Fork 1995 Clutch Fork 1994 Clutch Fork 1993 Clutch Fork 1992 Clutch Fork 1991 Clutch Fork 1990 Clutch Fork 1989 Clutch Fork 1988 Clutch Fork 1987 Clutch Fork 1986 Clutch Fork