×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Acura Parts

- Acura Accessories

My Garage

My Account

Cart

Genuine Acura Integra Crankshaft Position Sensor

Engine Crankshaft Position Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Crankshaft Position Sensors found

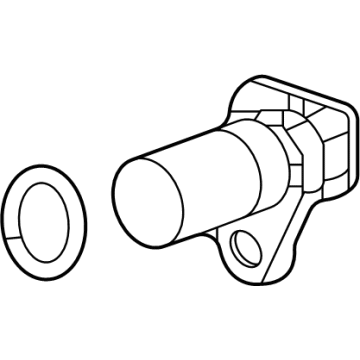

Acura Integra Sensor Assembly , Crank

Part Number: 37500-RPY-G01$86.08 MSRP: $120.77You Save: $34.69 (29%)Ships in 1-2 Business DaysAcura Integra Sensor Assembly , Crank

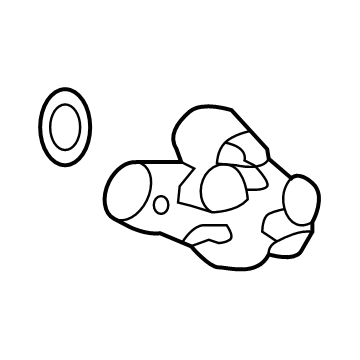

Part Number: 37500-59B-J01$68.12 MSRP: $95.00You Save: $26.88 (29%)Ships in 1-3 Business Days

Acura Integra Crankshaft Position Sensor

We provide a broad range of OEM Acura Integra Crankshaft Position Sensor at unbeatable prices on our website. For your OEM parts, You can count on the guaranteed quality, manufacturer's warranty, outstanding customer service, and prompt delivery. We look forward to your visit.

Acura Integra Crankshaft Position Sensor Parts Questions & Experts Answers

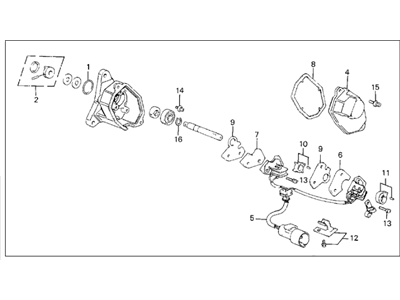

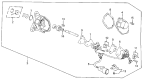

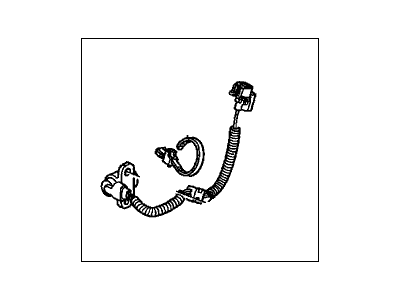

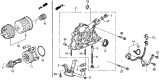

- Q: How does the crankshaft fluctuation sensor function and How to check and replace it on Acura Integra?A:The crankshaft fluctuation sensor features a pulse rotor on the front end of the crankshaft and a pickup sensor mounted on the engine adjacent to the rotor, with the PCM utilizing the signal to monitor changes in the crankshaft's rotational speed; if these changes surpass a predetermined limit, a misfire is indicated. To check the sensor, locate the electrical connector at the timing belt end of the engine, ensuring the key is in the OFF position before disconnecting it. An ohmmeter should be connected between the two outer terminals of the connector, with a reading of 1.6 to 3.2 k-ohms indicating proper function; if the reading is outside this range, the sensor needs replacement. Additionally, connecting the ohmmeter between body ground and each of the sensor's outer terminals should show no continuity; if it does, the sensor must be replaced. For replacement, remove the valve cover, crankshaft pulley, and timing belt cover, then disconnect the sensor's electrical connector and remove its mounting bolt, with installation following the reverse order of removal.

Related Acura Integra Parts

Browse by Year

2026 Crankshaft Position Sensor 2025 Crankshaft Position Sensor 2024 Crankshaft Position Sensor 2023 Crankshaft Position Sensor 2001 Crankshaft Position Sensor 2000 Crankshaft Position Sensor 1999 Crankshaft Position Sensor 1998 Crankshaft Position Sensor 1997 Crankshaft Position Sensor 1996 Crankshaft Position Sensor 1987 Crankshaft Position Sensor 1986 Crankshaft Position Sensor