×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Acura Parts

- Acura Accessories

My Garage

My Account

Cart

Genuine Acura MDX Oil Pump

Oil Fluid Pump- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

12 Oil Pumps found

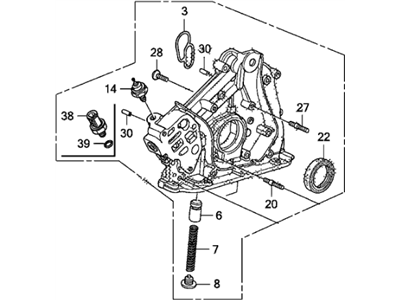

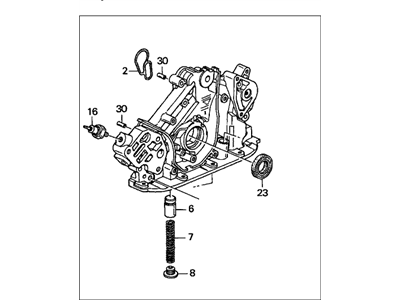

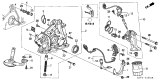

Acura MDX Oil Pump Assembly

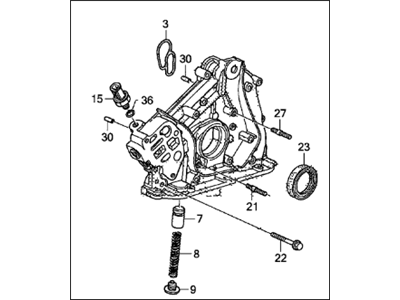

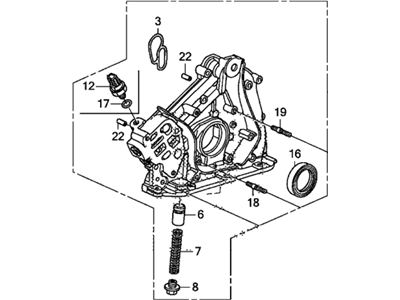

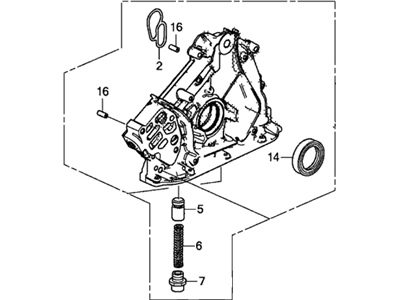

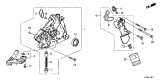

Part Number: 15100-RDM-A03$277.83 MSRP: $396.78You Save: $118.95 (30%)Ships in 1-2 Business DaysAcura MDX Engine Oil Pump

Part Number: 15100-RYE-A11$275.52 MSRP: $393.48You Save: $117.96 (30%)Ships in 1-3 Business DaysAcura MDX Oil Pump Assembly

Part Number: 15100-5G0-A01$63.60 MSRP: $88.70You Save: $25.10 (29%)Ships in 1-3 Business DaysAcura MDX Oil Pump Assembly (Yamada)

Part Number: 15100-R72-A02$243.82 MSRP: $348.22You Save: $104.40 (30%)Ships in 1-3 Business DaysAcura MDX Pump Assembly, Oil (Yamada)

Part Number: 15100-P8E-A01$338.16 MSRP: $482.95You Save: $144.79 (30%)Ships in 1-2 Business DaysAcura MDX Body Assembly, Oil Pump

Part Number: 25100-R9T-023$900.53 MSRP: $1286.10You Save: $385.57 (30%)Ships in 1-3 Business DaysAcura MDX PUMP ASSY., OIL

Part Number: 15100-6S9-A11$191.56 MSRP: $273.58You Save: $82.02 (30%)Ships in 1-2 Business Days

Acura MDX Oil Pump

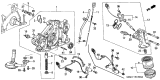

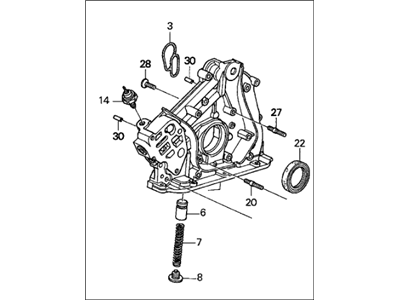

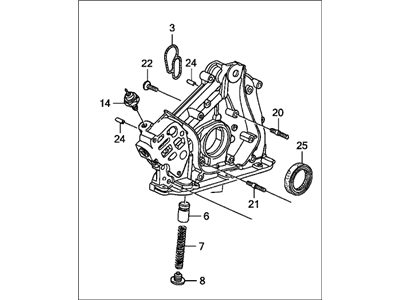

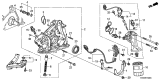

The Acura MDX Oil Pump is a crucial component that speaks directly of Acura's focus on reliable and high-performing automobiles. Intended to deliver proper operation of the engine, the Oil Pump forces the oil through the engine and provides lubrication and cooling of significant pieces, including bearings, pistons, and the camshaft. This system improves engine efficiency and plays a very important role in the safety of the vehicle by preventing overheating and failure due to constant wear. One replaceable part is the Oil Pump, which serves different generations of the MDX, and the strong conception and creation of this component do not disappoint. Playing a major role in maintaining oil pressure, the Oil Pump is an inseparable part of the MDX's performance, which depends on oil viscosity and temperature factors. The oiling system includes ways of drawing oil from the sump, filtering, and cooling the oil before distribution, which is important for engine operation. Some outstanding features of the Acura MDX Oil Pump are primarily associated with its mechanical type, driven by the crankshaft or camshaft, to enhance the reliability of the Acura. This additional component contributes to the image associated with the brand, corresponding to a luxurious and high-performance vehicle, thus making the Oil Pump rather unique in the automotive industry. To make an Oil Pump last longer and keep the Acura MDX running as safely and powerfully as it did on the first day, owners should adhere to the time-tested rule of timely oil and filter changes.

We provide a broad range of OEM Acura MDX Oil Pump at unbeatable prices on our website. For your OEM parts, You can count on the guaranteed quality, manufacturer's warranty, outstanding customer service, and prompt delivery. We look forward to your visit.

Acura MDX Oil Pump Parts Questions & Experts Answers

- Q: How to remove and reinstall an oil pump in the Acura MDX?A:Remove the crankshaft position sensor. Remove the Timing Belt, crankshaft sprocket, and idler pulley. Remove the Oil Pan and oil pick-up screen. If equipped, remove the oil level sensor. Remove the oil filter adapter housing/VTEC solenoid assembly (4WD models) from the front of the oil pump. Remove the bolts and detach the oil pump housing from the engine. You may have to pry carefully between the main bearing cap and the pump housing with a screwdriver. Use a Phillips screwdriver to remove the screws holding the pump cover to the rear of the housing. Lift the cover off and inspect the pump rotors. If any wear or damage is evident, replace the pump. Check the rotor clearance with a feeler gauge and compare it. Use a scraper to remove any traces of old sealant from the pump body and engine block, being careful not to damage the delicate aluminum. Replace the old crankshaft oil seal. Apply engine oil or multi-purpose grease to the seal lip. Pack the pump cavities with petroleum jelly and install the cover. Apply thread-locking compound to the threads and tighten the screws. Use acetone or lacquer thinner and a clean rag to remove all traces of oil from the gasket surfaces. Apply a bead of anaerobic sealant to the oil pump flange and the threads of the mounting bolts. Avoid using an excessive amount of sealant, especially around oil passages and bolt holes. Parts must be assembled within five minutes of sealant application, otherwise, the material must be removed and reapplied. Wherever O-rings are employed, use new ones. Engage the flat surfaces on the oil pump drive rotor with the matching flats on the crankshaft and slide the pump into place. Install the pump mounting bolts in their original locations and tighten them. Using a new O-ring, install the oil pick-up screen and tighten the fasteners. Reinstall the remaining parts in the reverse order of removal. Wait 30 minutes to allow the sealant to cure, then add oil, start the engine, and check for oil leaks and pressure. Recheck the engine oil level after operating the engine.

Related Acura MDX Parts

Browse by Year

2026 Oil Pump 2025 Oil Pump 2024 Oil Pump 2023 Oil Pump 2022 Oil Pump 2020 Oil Pump 2019 Oil Pump 2018 Oil Pump 2017 Oil Pump 2016 Oil Pump 2015 Oil Pump 2014 Oil Pump 2013 Oil Pump 2012 Oil Pump 2011 Oil Pump 2010 Oil Pump 2009 Oil Pump 2008 Oil Pump 2007 Oil Pump 2006 Oil Pump 2005 Oil Pump 2004 Oil Pump 2003 Oil Pump 2002 Oil Pump 2001 Oil Pump