×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Acura Parts

- Acura Accessories

My Garage

My Account

Cart

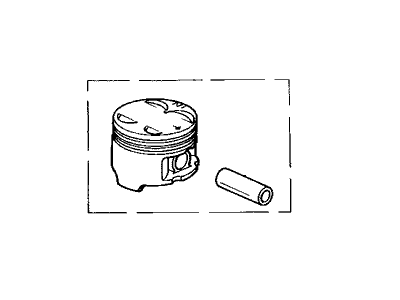

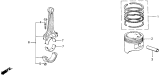

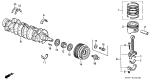

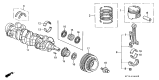

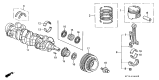

Genuine Acura Integra Rod Bearing

Engine Connecting Rod Bearing- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

43 Rod Bearings found

Acura Integra Clutch Pilot Bearing

Part Number: 91006-RK2-003$25.78 MSRP: $35.95You Save: $10.17 (29%)Ships in 1-3 Business Days

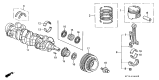

Acura Integra Connecting Rod Yellow Set

Part Number: 13215-P72-003$14.66 MSRP: $20.45You Save: $5.79 (29%)Ships in 1-3 Business Days

Acura Integra Engine Connecting Rod Bearing D (Green) (Daido)

Part Number: 13214-P72-003$22.19 MSRP: $30.95You Save: $8.76 (29%)Ships in 1-3 Business Days

Acura Integra Connecting Rod (Red) (Daido) Bearing G

Part Number: 13217-P72-003$14.66 MSRP: $20.45You Save: $5.79 (29%)Ships in 1-3 Business Days

Acura Integra Connecting Rod Bearing F (Pink) (Daido)

Part Number: 13216-P72-003$14.66 MSRP: $20.45You Save: $5.79 (29%)Ships in 1-3 Business DaysAcura Integra Connecting Rod Bearing C (Brown) (Daido)

Part Number: 13213-P72-003$22.19 MSRP: $30.95You Save: $8.76 (29%)Ships in 1-3 Business DaysAcura Integra Bearing E, Connecting Rod

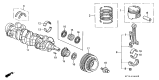

Part Number: 13215-5A2-A01$16.73 MSRP: $23.33You Save: $6.60 (29%)Ships in 1-3 Business DaysAcura Integra Bearing D, Connecting Rod

Part Number: 13214-5A2-A01$16.73 MSRP: $23.33You Save: $6.60 (29%)Ships in 1-3 Business DaysAcura Integra Bearing B, Connecting Rod

Part Number: 13212-5A2-A01$16.73 MSRP: $23.33You Save: $6.60 (29%)Ships in 1-3 Business DaysAcura Integra Bearing H, Connecting Rod (White) (Daido)

Part Number: 13218-5A2-A01$16.73 MSRP: $23.33You Save: $6.60 (29%)Ships in 1-3 Business DaysAcura Integra Bearing G, Connecting Rod

Part Number: 13217-5A2-A01$16.73 MSRP: $23.33You Save: $6.60 (29%)Ships in 1-3 Business DaysAcura Integra Bearing, Connecting Rod

Part Number: 13216-5A2-A01$16.73 MSRP: $23.33You Save: $6.60 (29%)Ships in 1-3 Business DaysAcura Integra Bearing C, Connecting Rod

Part Number: 13213-5A2-A01$16.73 MSRP: $23.33You Save: $6.60 (29%)Ships in 1-3 Business DaysAcura Integra Bearing G, Connecting Rod (Red) (Daido)

Part Number: 13217-PG6-003$17.33 MSRP: $24.17You Save: $6.84 (29%)Ships in 1-3 Business DaysAcura Integra Bearing F, Connecting Rod (Pink) (Daido)

Part Number: 13216-PG6-003$18.12 MSRP: $25.27You Save: $7.15 (29%)Acura Integra Bearing E, Connecting Rod (Yellow) (Daido)

Part Number: 13215-PG6-003$18.12 MSRP: $25.27You Save: $7.15 (29%)Ships in 1-3 Business DaysAcura Integra Bearing D, Connecting Rod (Green) (Daido)

Part Number: 13214-PG6-003$18.12 MSRP: $25.27You Save: $7.15 (29%)Ships in 1-3 Business DaysAcura Integra Bearing C, Connecting Rod (Brown) (Daido)

Part Number: 13213-PG6-003$18.12 MSRP: $25.27You Save: $7.15 (29%)Ships in 1-3 Business Days

| Page 1 of 3 |Next >

1-20 of 43 Results

Acura Integra Rod Bearing

We provide a broad range of OEM Acura Integra Rod Bearing at unbeatable prices on our website. For your OEM parts, You can count on the guaranteed quality, manufacturer's warranty, outstanding customer service, and prompt delivery. We look forward to your visit.

Acura Integra Rod Bearing Parts Questions & Experts Answers

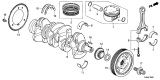

- Q: What are the essential considerations during engine overhaul regarding the examination and selection of main and connecting rod bearings on Acura Integra?A:When doing an engine overhaul, you will need to keep the old main and Connecting Rod bearings, since they may give insight into the engine's condition. Inadequate lubrication, dirt contamination, overloading, and corrosion all contribute to bearing failure which must be addressed prior to reassembly, or the problem will continue to occur. Remove the bearings from their location and arrange them on a clean surface for matching problems when inspecting the bearings with the Crankshaft journal. Foreign particles can get into the engine through various sources such as assembly debris, filter bypass, and machining debris, and can embed in the bearing material foreign particles can embed in the bearing material or, if large enough, cause scoring. In order to avoid such failures, all the components need to be completely cleaned and regular oil changes are necessary. Severe damage can result from lubricant breakdown arising from such factors, excessive heat, overloading, oil leakage and blocked passages. Bearing longevity is also a function of driving habits; a common contributor to fatigue failures is low speed, full throttle operation, while short trips dry out bearings and hasten corrosion. This can compound the problem, and may leave the engine without oil or with high points on bearings. If the originals are worn or the oil clearance is incorrect, use oil clearance measurements as a guide when selecting new bearings. When replacing main bearings, the color code of the new bearing should match that which is on the original, or obscured, and in the latter case, the markings stamped on the block and crankshaft should be consulted. The same is true with a stamped number indicating what bore size a connecting rod bearing was. Ultimately, bearing selection is based upon the oil clearance as a final determinant, although failing that, a dealer's assistance may be required.

Related Acura Integra Parts

Browse by Year

2026 Rod Bearing 2025 Rod Bearing 2024 Rod Bearing 2023 Rod Bearing 2001 Rod Bearing 2000 Rod Bearing 1999 Rod Bearing 1998 Rod Bearing 1997 Rod Bearing 1996 Rod Bearing 1995 Rod Bearing 1994 Rod Bearing 1993 Rod Bearing 1992 Rod Bearing 1991 Rod Bearing 1990 Rod Bearing 1989 Rod Bearing 1988 Rod Bearing 1987 Rod Bearing 1986 Rod Bearing