×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Acura Parts

- Acura Accessories

My Garage

My Account

Cart

Genuine Acura Legend Piston Rings

Piston Ring Set- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

20 Piston Rings found

Acura Legend Piston Rings

We provide a broad range of OEM Acura Legend Piston Rings at unbeatable prices on our website. For your OEM parts, You can count on the guaranteed quality, manufacturer's warranty, outstanding customer service, and prompt delivery. We look forward to your visit.

Acura Legend Piston Rings Parts Questions & Experts Answers

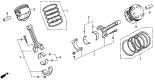

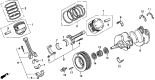

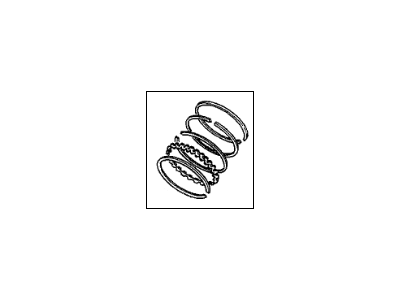

- Q: How should you check and install piston rings on Acura Legend?A:Check the ring end gaps, before installing the rings, to make sure the side clearance of the piston ring has been verified. During end gap measurement and engine assembly, match the piston and the cylinder with the corresponding piston and Connecting Rod assemblies and new ring sets laid out on the workbench. Seal the top ring to the first cylinder, so it's square with the cylinder walls, and push the top of the piston in to square it with the cylinder wall and get it in near the bottom of the cylinder. Use feeler gauges between the ends of the ring and find the correct gauge that will slide with slight drag. Check the rings and verify if the gap is within the specifications, otherwise run again. If the gap is too small file the ends and replace rings. As long as there is no excess end gap beyond 0.040 inch on the rings, it's not critical, but make sure rings are not obsolescent. Repeat this for each cylinder in the first cylinder and all remaining cylinders; match and keep rings, Pistons, and cylinders in place. Once you've checked and correctly corrected the end gaps, install the rings on the pistons, beginning with the oil control ring made of three pieces. Put the spacer/expander into the groove, ensuring the anti rotation tang is in the correct position (no scratch on the ring) then install the lower side rail but without a ring installation tool. Do the same on the upper side rail, only that both should turn in the groove smoothly. The thing was then to install the middle ring next, facing so the identification mark is on the top, and did so with a piston ring installation tool to slide it into the middle groove without overexpansion. Now, finally, install the press ring into this same way, the mark must be standing up and repeat the procedure for the other pistons and rings.