×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Acura Parts

- Acura Accessories

My Garage

My Account

Cart

Genuine Acura Integra Pistons

Engine Pistons- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

23 Pistons found

Acura Integra Piston (Over Size) (0.25)

Part Number: 13102-P29-000$8.11 MSRP: $65.40You Save: $57.29 (88%)Ships in 1-2 Business DaysAcura Integra Piston Set

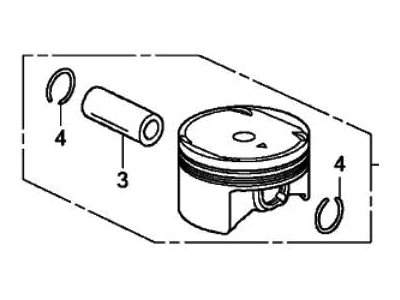

Part Number: 13020-66V-A00$206.52 MSRP: $294.95You Save: $88.43 (30%)Ships in 1-2 Business DaysAcura Integra Piston Set

Part Number: 13010-66V-A00$69.98 MSRP: $97.60You Save: $27.62 (29%)Ships in 1-2 Business DaysAcura Integra Piston Set (Std)

Part Number: 13010-5PA-A00$63.96 MSRP: $89.20You Save: $25.24 (29%)Ships in 1-3 Business Days

| Page 1 of 2 |Next >

1-20 of 23 Results

Acura Integra Pistons

We provide a broad range of OEM Acura Integra Pistons at unbeatable prices on our website. For your OEM parts, You can count on the guaranteed quality, manufacturer's warranty, outstanding customer service, and prompt delivery. We look forward to your visit.

Acura Integra Pistons Parts Questions & Experts Answers

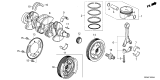

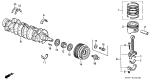

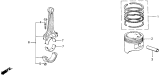

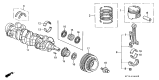

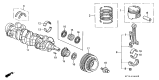

- Q: What steps must be taken before removing the piston and connecting rod assemblies on Acura Integra?A:Prior to removing the piston and connecting rod assemblies, the cylinder head, oil pan, oil pump pick-up tube, pump, and baffle plate must be taken off. Use your fingernail to check for any ridges at the upper limit of ring travel, approximately 1/4-inch down from the top of each cylinder. If ridges are present due to carbon deposits or cylinder wear, they must be completely removed with a special tool, as failure to do so may result in piston breakage. After addressing any cylinder ridges, turn the engine upside-down with the Crankshaft facing up. The bearing cap bridge should be removed first to access the connecting rods, except for specific DOHC non-VTEC engines. Before removing the connecting rods, check the side clearance with feeler gauges, ensuring that the endplay does not exceed the service limit; if it does, new connecting rods may be necessary. The existing numbers on the connecting rods indicate the rod bore size, not their position in the engine, so mark each rod and cap with indentations corresponding to their associated cylinder numbers. Loosen the connecting rod cap nuts gradually until they can be removed by hand, then take off the number one connecting rod cap and bearing insert without dropping the insert. To protect the crankshaft journal and cylinder wall during piston removal, slip a short length of plastic or rubber hose over each connecting rod cap bolt. Remove the bearing insert and push the connecting rod/piston assembly out through the top of the engine, using a wooden hammer handle to apply pressure on the upper bearing surface. If resistance is encountered, ensure that all ridges have been removed from the cylinder. Repeat this process for the remaining cylinders. After removal, reassemble the connecting rod caps and bearing inserts in their respective rods and install the cap nuts finger tight to prevent accidental damage to the bearing surfaces. Avoid separating the pistons from the connecting rods.